FOCUSED ON ENSURING THAT THE MAXIMUM VALUE IS DERIVED FROM ANY PRODUCTION PROCESS OR ASSET.

Our team of engineers, operations research professionals, data engineers, simulation specialists and data scientists are dedicated to improving both the efficiency and effectiveness of business, production, and processing operations.

Productivity Science is able to

Maximise Return on Capital Employed (ROCE) through better asset configuration and utilisation

Maximise Production volumes through better operational planning and constraint management

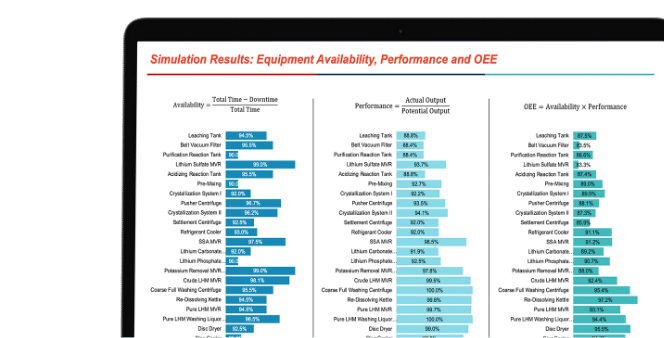

Maximise OEE potential through better operational efficiencies and coordination

Reduce variability in key activities and processes

Reduce inefficiencies during execution and short-term replanning

Reduce residual risk and wastage

Provide actionable

recommendations to maximise operational

performance

Our value offerings

cover Process Design, Operational Planning and Execution Support

PRODUCTIVITY SCIENCE achieves this by clearly defining what productivity metrics are critical for your operation, relating the cause and effect that underpins these metrics (through Modelling, Digital Twin Simulations and Value Driver Analysis) and finally, working closely with your team to drive organisational alignment and change management by testing and evaluating options and initiatives.

Ultimately, we provide clients with the skills to derive and manage a self-sustained improvement agenda by understanding production operations in a way your competitors do not.

Specific Services and Solutions offered

Validation

Studies

Providing confidence on the business impact of commissioning new operations or making major changes to your existing operational assets, processes or resources.

Operational

Diagnostic

Identifying the critical KPIs behind underperformance or lost opportunities, enabling your team to drive better operational improvement and planning.

Operational

Planning

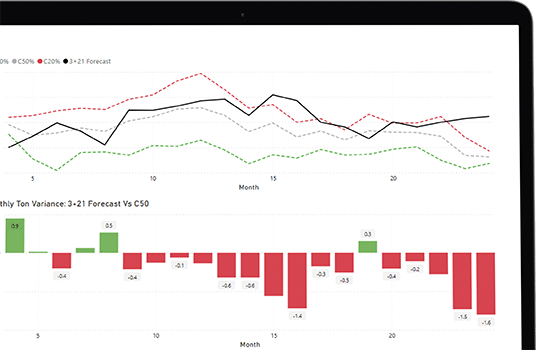

Determining the most optimal production plan, taking into consideration existing resources, assets, and constraints.

Execution

Support

Augmenting an operational controller’s ability to deliver optimally, by being informed of the next best plan when deviations or disruptions occur in the short term.

WITNESS Simulation

Modelling Software

BSC is an approved reseller of WITNESS – the most flexible, powerful, proven process simulation technology in the world.

TESTIMONIALS

This is the first time I have been involved in a logistics study of this nature. The rigour and credibility of the team and the range of the model results exceeded my expectations. Well don

The team is highly motived to deliver a quality result and work hard to achieve that.

A highly professional team and highly driven to get the job done.

All the outputs were extremely useful in dispelling ‘urban myths’ and providing opportunities for improvement.

The solution delivered is going to add great value to our sites going forward. The technical aspect was to a very high standard, and the ability of key people in the project team to pick up and understand a complex mining process was excellent. Overall a great first project with the BSC team.

Great team, really gets stuck in to the hard & complex tasks.

The team is dynamic and has suitable technical skills assisted by a single competent project manager improving communication and understanding. The information interpretation and visualisation is of outstanding quality.

BSC conducted an analysis of the South Deep Gold Mine rail-bound tramming capacity to verify if it can sustain the production profile. Real-time data was used to build the analysis model and a very valuable report was delivered. I will recommend BSC as a valuable stakeholder in any mine’s success.

I have always been impressed with their ability to understand the scope of the problem and in turn to articulate a solution that can add value to the business.

Really happy with the commitment from the team. They always make sure they understand our needs and make effort to address our concerns. Always a pleasure working with BSC.

INTERESTED IN OUR

PRODUCTIVITY SCIENCE SOLUTIONS?

TRUSTED BY

TOP BRANDS, GLOBALLY

For the past 20 years, BSC has mastered the application of analytics and smart technology to increase business performance.